Frequency: 15KHZ-20KHZ

Power: 3500W-6500W

Body weight: 290KG

Control system: servo control

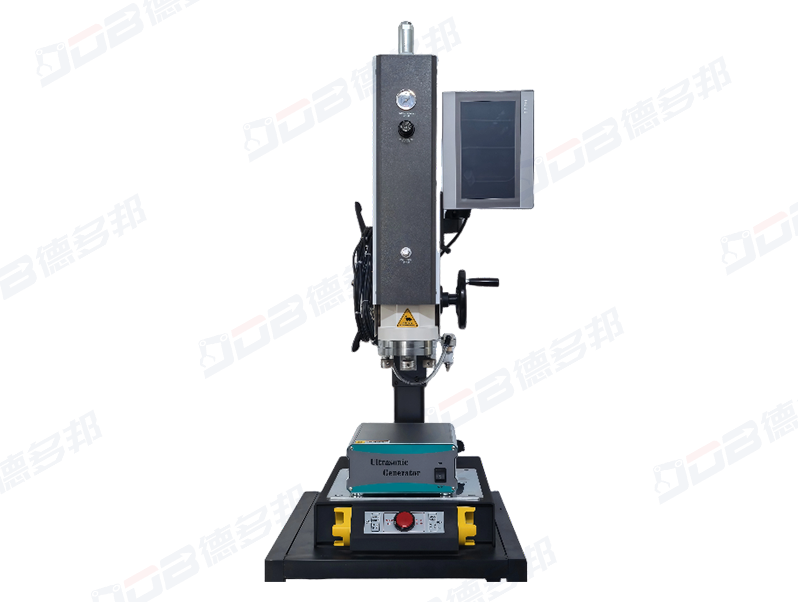

Product Descriptions

Mold movement uses precision sliders and rails for accurate alignment, stability, and durability. Latest servo drive enables variable-speed mold lifting, adjustable to needs. Chrome-plated steel workbench with M10 rice-pattern holes fits various workpieces; horizontal screws ensure perfect mold fit for better welding. Digital visual auto-frequency-tracking ultrasonic system with harmonic circuits enables efficient, precise welding.

Integrates multiple welding controls, including 0.01mm precision full-closed-loop servo stroke. Features data storage/transmission, fault self-detection, welding anomaly monitoring, and seamless MES/PC integration.

Advantages

Electrical and electronic industry

Used for welding switching power supplies, chargers, battery casings, etc. They achieve molecular fusion of plastic and metal through high-frequency vibration without the need for high temperatures, ensuring waterproof and dustproof performance, and significantly improving product yield

High-precision instrument industry

Equipped with high-precision servo motors, the welding accuracy can reach 5μm. It can accurately align weld seams, optimize welding quality, reduce the risk of product cracks and fractures, and meet the strict requirements for welding accuracy in the high-precision instrument industry

Automotive industry

It can be used for welding automotive interior parts, exterior parts, engine compartment components, etc., such as the welding of parts like car lights, bumpers, instrument panels, and door interiors

Plastic industry

It is widely used in the assembly of toys, the bonding of stationery, the welding of home appliance casings, the packaging of plastic casings for electronic products, etc

Equipment Parameters

| Model | Servo welding machine |

| Intelligent Management | Amplitude/Quality/Recipe/Data/Safety management |

| Power | 3500W-6500W |

| Body Weight | 290KG |

| Frequency | 15KHZ/20KHZ |

| Operation Interface | 10-inch touch screen 10-inch suspended color touch screen |

| Input Voltage | AC220V |

| Control System | servo control |

| Language | English |

| Body Size | 800*930x1900m |

| Working Mode | button/external control mode |

| Z-Axis Precision | 0.01mm |

| Functional Features | Supports multiple recipe calls |

| Welding Mode | time mode/energy mode/depth mode/absolute depth/relative depth/pressure mode |

Application Industry

1. Intelligent stepped amplitude

2. Digital visual automatic frequency tracking system

3. Horizontal adjustment for quick replacement of upper and lower molds

4. Precision sliding slider and linear guide, with small error

5. Servo drive combined with servo motor, variable speed lifting

6 .trigger modes and 3 welding modes

7.ypes of quality monitoring to ensure welding quality

8.New IoT control system

9.Can be connected to MES system (customized) for data upload

10.Fault self-inspection and abnormality monitoring

11.Human-machine interface, with welding record query/storage/export

Let's provide you with quality solutions

Are you interested in a product, need a consultation or would like to have a quote?

Related Products

Navigation

Navigation

Contact

Tel.: +18770615877

E-mail: deduobang@gmail.com

WhatsApp: +8618770615877

WeChat:18770615877

navigation: Huaguang Industrial Park, No.9 Jinyun Street, Haishu District, Ningbo City